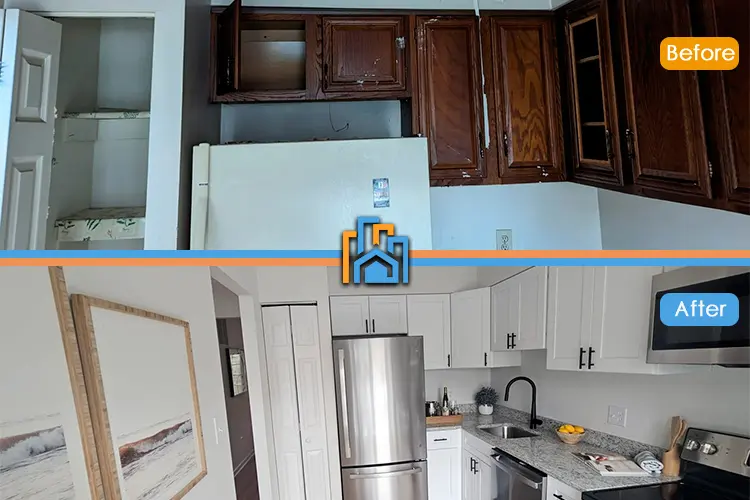

Our company performed a complete kitchen remodel in Silver Spring, MD after severe flood damage. The owner needed to sell the house and completely restore it. We use specialized tools and advanced techniques to ensure high-quality work, complying with all safety regulations and guaranteeing customer satisfaction.

Work Done in the Kitchen

The kitchen remodel project included cleaning the air with an air purifier due to moisture in the drywall. A special paint was applied to prevent mold. New 1/4 turn valves were installed and the refrigerator water line was replaced with copper using the Propress no-solder system to prevent future leaks. New appliances, lights, switches and outlets were also installed. The soil used was 7 ml LVP. Work was done at night to stop the leak and the kitchen remodel was completed within a week.

Main Points of the Work Done:

- Demolition

- Cleaning the air with an air purifier

- Application of special anti-mold paint

- Installing new 1/4 turn valves

- 7ml LVP soil

- Check all pipes for water leaks.

- Drywall installation.

- Installation of new appliances, lights, switches and outlets

- Refrigerator Water Line Replacement with Copper and Propress System

- Counter top installation.

- Hardware installation.

- Cabinet installation.

Components and Tools Used

For this project, we used a variety of specialized components and tools. The air purifier was essential to eliminate moisture in the drywall, while the anti-mold paint ensured a healthy, fungus-free environment. The 1/4 turn valves and copper water line with the Propress system offered long-lasting, leak-free solutions. Additionally, new appliances and modern lighting significantly improved the functionality and appearance of the kitchen. The 7ml LVP flooring provided a durable and aesthetic surface.

Steps and Safety Devices Used

To ensure safety during the project, we followed several critical steps. First, we identified and stopped the water leak immediately. Next, we use an air purifier to remove moisture and prevent mold problems. We applied anti-mildew paint to ensure the area was free of contaminants. During copper water line installation, we use the Propress system, which eliminates the need for soldering and reduces the risk of future leaks. Additionally, we ensured that all new appliances, lights, switches and outlets were installed following electrical safety regulations. Finally, the LVP flooring was carefully laid to prevent accidents and ensure a safe, long-lasting surface.

This detailed and careful approach ensured high quality work, fully meeting the owner’s needs and restoring the property’s functionality and value.